As of today, there are over a dozen major chip companies globally, and with the release of production capacity from larger factories, smaller ones are finding it increasingly difficult to secure orders. Liu Wenhui, the director of Ganzhao Optoelectronics, made this observation during Huatai Securities' 2017 interim strategy meeting.

This year, several key players are ramping up production. Over the past few years in China’s LED industry, there has been significant progress in areas such as high-end equipment, chip manufacturing, packaging, technology, product quality, scale, and global competitiveness.

According to plans, Sanan's monthly production capacity is expected to rise to 2.5 million pieces from 1.8 million in 2017, while Huacan aims for a monthly output of 1.5 million pieces. In two years, the industry landscape might stabilize, leaving little room for smaller competitors. Market share and production capacity will likely consolidate further among leading manufacturers.

By the end of 2017, the top three mainland chip producers will account for nearly 60% of total capacity. For these businesses, deciding whether to expand production has become a matter of survival. Without scaling up, they risk losing their industrial standing and facing extinction.

The oligarchic structure of the LED chip industry may have already peaked in the last two years, with future stability likely ensuring no opportunities for laggards. Over the past decade, the global LED market has grown annually by over 20%. With ongoing technological advancements and cost reductions, the market is poised for continued rapid growth, particularly in the lighting sector.

Data from the Advanced Industrial Research LED Institute (GGII) shows that the global LED chip market reached 44.8 billion yuan in 2016, up 7.88% from the previous year. It is projected that China’s LED core output value will reach 28.8 billion yuan by 2020, growing at an annual rate of 12%.

[Table showing the scale and forecast of China’s LED chip output value from 2014 to 2020]

[Graph showing the scale of global LED chip production from 2010 to 2016]

Since the start of this year, Huacan Optoelectronics, Ganzhao Optoelectronics, and Zhaochi have all embarked on significant expansions, collectively investing 16 billion yuan in chip production.

Ganzhao Optoelectronics plans a 5-billion-yuan investment to expand its LED epitaxial chip production. The company announced it would invest 5 billion yuan (in two phases) in the Nanchang New District of Jiangxi Province to create a blue-green chip production base with a monthly output of 1.2 million pieces (2 inches). The initial investment is expected to be 2.5 billion yuan, establishing a base capable of producing 600,000 pieces per month. Based on the need for expanding its blue-green business, Ganzhao Optoelectronics plans to establish a wholly-owned subsidiary in Jiangxi Province with 300 million yuan in self-owned capital to support this expansion. The target markets include lighting, displays, and backlights.

Huacan Optoelectronics’ Yiwu plant area, after nearly a year of construction, officially began operations on July 15. President Liu Wei stated that the commissioning of the Yiwu plant marks the successful completion of the first phase of Huacan’s capacity expansion. By year-end, the company’s 4-inch LED chip capacity is expected to reach 425,000 pieces per month, alleviating current shortages and boosting market share.

The Yiwu plant area plans a total investment of 6 billion yuan over 280 acres, increasing LED epitaxial chip production by 250,000 pieces per month upon completion. The first phase, costing 3 billion yuan and covering 140 acres, will produce 150,000 LED chips and 200,000 sapphire substrates per month by year-end.

Domestic manufacturers like Sanan and Huacan are leading the expansion. Huacan’s capacity has grown from 200,000 pieces per month in 2016 to 425,000 pieces in 2017, doubling its output. This expansion has significantly boosted the company’s revenue.

Huacan now operates four production bases in Wuhan, Suzhou, Yuxi, and Yiwu. Additionally, it acquired upstream sapphire substrate producer Lanjing Technology, integrating epitaxial chip and sapphire substrate production. Yiwu will become Huacan’s largest production base, driving downstream enterprises to invest in Yiwu. Mulinsen, China’s largest packaging company, will also invest 5.5 billion yuan in Yiwu.

Zhaochi shares is making a 5-billion-yuan move into LED upstream chip production. In June, Zhaochi announced plans to set up a project company in Nanchang’s high-tech industrial development zone, focusing on LED epitaxial wafer and chip production, R&D, and sales. The first phase of the project plans a joint investment of 5 billion yuan (including land, plant construction, and renovations), with equipment investment of no less than 3 billion yuan, meaning the project company’s registered capital will be at least 3 billion yuan.

Under the premise of meeting construction, renovation, and operational conditions, the first phase of the project is scheduled to be installed and operational in 2018.

The Nanchang High-tech Industrial Development Zone Management Committee will apply for the Nanchang Key Industry Development Fund for Jiangxi Zhaochi Semiconductor. The Industrial Development Fund will invest 1.5 billion yuan, not exceeding 50% of the project company’s registered capital.

According to the announcement, the LED industry extends and expands the company’s existing industrial chain, becoming a crucial business segment for Zhaochi. With business scale expansion, the company’s demand for LED chips has risen significantly, along with industry consolidation showing the trend toward vertical integration across the entire supply chain.

After the project company begins operations, it is expected to contribute approximately 60-70 billion yuan in additional production value to the company through coordinated development of the LED industry chain.

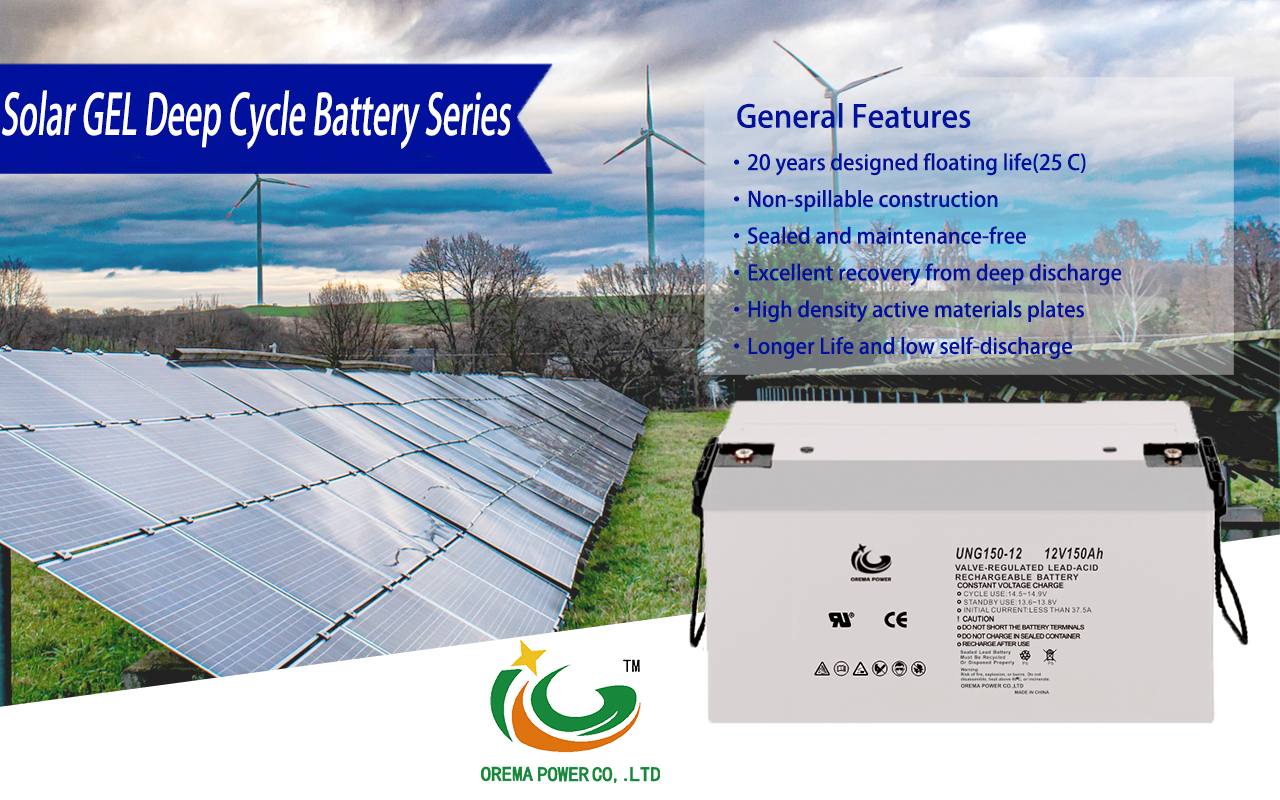

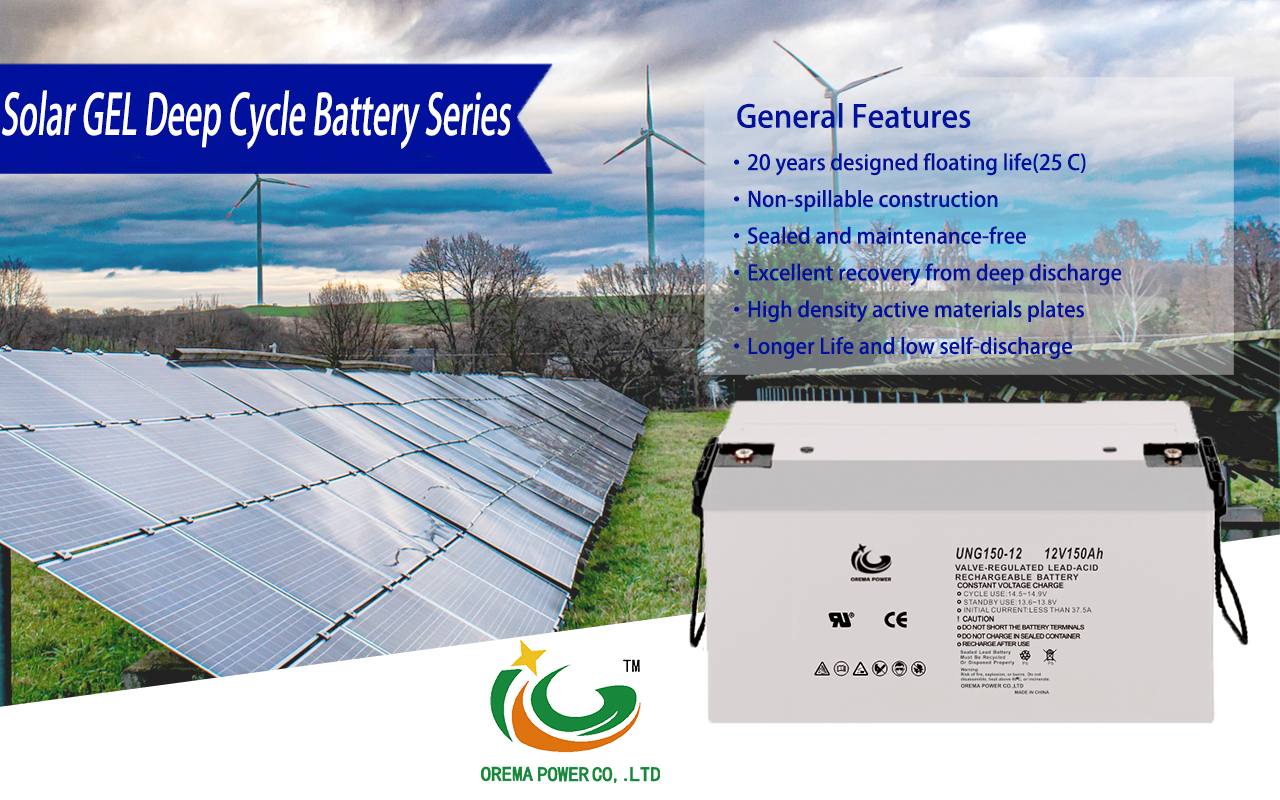

Discover the OREMA Solar GEL Deep Cycle Batteries, engineered with cutting-edge technology and rigorous quality assurance processes to deliver unparalleled performance and reliability. These batteries, featuring special separators and silica gel, are the epitome of innovation in the lead acid battery market.

Key Features of OREMA Solar GEL Battery:

1. Advanced Silica Gel Technology: OREMA uses silica gel to immobilize the electrolyte, enhancing cycle life and performance across a broad temperature range. This technology offers a 50% longer cycle life compared to standard AGM batteries.

2. Environmentally Friendly and Maintenance-Free: With their non-spillable construction and environmentally friendly design, these batteries require no maintenance, making them a hassle-free choice for users.

3. Wide Operating Temperature Range: Functioning efficiently between -20°C and +60°C, these batteries are designed to withstand extreme conditions without compromising performance.

4. Safety and Reliability: Features like explosion-proof construction, valve regulation, and high discharge rate capability ensure safety and dependability.

5. Efficient Energy Storage: Low self-discharge rates and ease of shipment make these batteries an ideal choice for various applications.

6. Convenience and Versatility: No need for balanced charge or boost, and no memory effect, ensuring ease of use in diverse settings.

7. Certified Quality: Adhering to stringent ISO quality management systems, OREMA has earned certifications like UL, CE, IEC, and ROHS, affirming its superior quality.

2. Environmentally Friendly and Maintenance-Free: With their non-spillable construction and environmentally friendly design, these batteries require no maintenance, making them a hassle-free choice for users.

3. Wide Operating Temperature Range: Functioning efficiently between -20°C and +60°C, these batteries are designed to withstand extreme conditions without compromising performance.

4. Safety and Reliability: Features like explosion-proof construction, valve regulation, and high discharge rate capability ensure safety and dependability.

5. Efficient Energy Storage: Low self-discharge rates and ease of shipment make these batteries an ideal choice for various applications.

6. Convenience and Versatility: No need for balanced charge or boost, and no memory effect, ensuring ease of use in diverse settings.

7. Certified Quality: Adhering to stringent ISO quality management systems, OREMA has earned certifications like UL, CE, IEC, and ROHS, affirming its superior quality.

Applications of OREMA Solar Deep Cycle Gel Battery:

- Communication and telecommunication control equipment

- Emergency and security systems, including fire and alarm systems

- Electric power systems, including power stations and nuclear power stations

- Renewable energy systems like solar and wind power

- Marine and medical equipment

- Uninterruptible power supplies

- Emergency and security systems, including fire and alarm systems

- Electric power systems, including power stations and nuclear power stations

- Renewable energy systems like solar and wind power

- Marine and medical equipment

- Uninterruptible power supplies

Why OREMA Solar Deep Cycle Gel Batteries?

With over 20 years of industry experience, state-of-the-art equipment, and 12 automated production lines, OREMA is dedicated to delivering perfection to its clients. Our customer-oriented approach and understanding of client needs have propelled us to a prominent position in the global lead-acid battery market. We offer OEM, ODM, and advanced customization services to over 80 countries, ensuring fast delivery within 30 days for in-stock products.

OREMA GEL Batteries represent the pinnacle of solar gel battery quality in China. Choose OREMA Solar GEL Deep Cycle Battery Series UNG for a reliable, efficient, and environmentally friendly power solution. Contact us for more information or to place your order today!

OREMA GEL Batteries represent the pinnacle of solar gel battery quality in China. Choose OREMA Solar GEL Deep Cycle Battery Series UNG for a reliable, efficient, and environmentally friendly power solution. Contact us for more information or to place your order today!

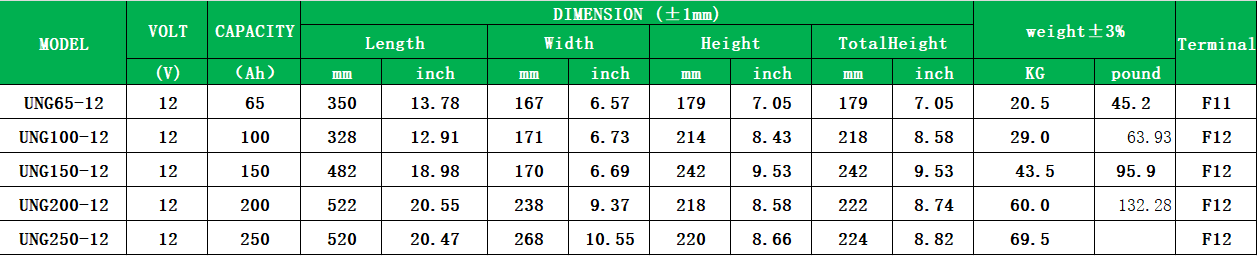

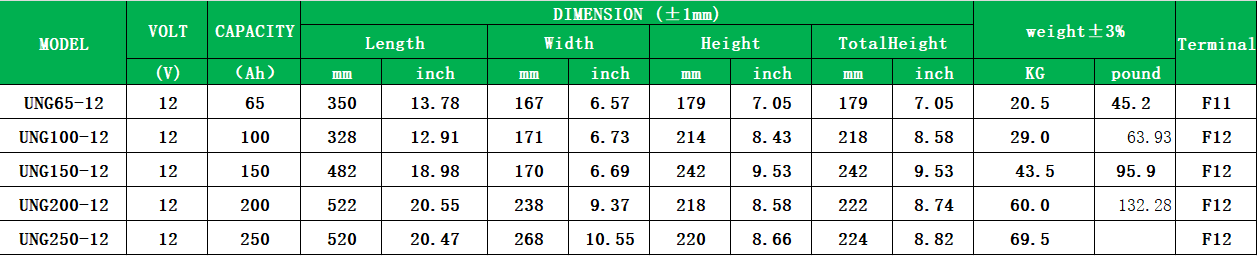

OREMA Solar GEL Deep Cycle Battery series GEL batteries specification table

12V Solar GEL Deep Cycle Batteries,solar gel battery,Gel Batteries,deep cycle gel battery,telecom battery,inverter battery

OREMA POWER CO., LTD. , https://www.oremapower.com